Last week the Environmental Protection Agency (EPA) proposed Clean Air Act mercury and air toxics standards to curb harmful emissions from the nation’s fleet of aging and dirty power plants fueled by coal and oil. The rule is part of a package of EPA rules that strive to make electricity generation a cleaner process, so that power plants do not continue to pollute the air and endanger people’s health.

The Mercury and Air Toxics Standards, as the name suggests, will drive deep cuts in levels of mercury and other dangerous pollutants including arsenic, lead, heavy metals, dioxins and acid gases that threaten public health and impede child development. Even in small amounts, these extremely harmful air pollutants are linked to health problems including cancer, asthma, heart disease, neurological damage, birth defects and even premature death. The Mercury and Air Toxics Standards promise to significantly reduce air pollution, including mercury emissions from power plants burning coal and oil by 91%, acid gas pollution by 91%, direct particulate matter (PM) emissions by 30% and sulfur dioxide (SO2) emissions by 53%, down to 2.1 million tons of annual SO2 emissions.

The standards will also deliver tremendous health benefits, including up to 17,000 American lives saved every year by 2015. For more information on the proposed rule’s benefits and history, see my colleague John Walke’s blog here.

In tandem with the environmental and health benefits, power plant owners and operators will have opportunities to comply with the rule using a number of economically prudent and readily available resources. EPA estimates compliance capital costs to be approximately $10.9 billion annually, compared with annual monetized benefits of $59 billion to $140 billion. These are driven by controls for particulate matter (soot) and acid gases, weighing heavily in favor of dry scrubbers, fabric filters, dry injection systems and activated carbon injection over wet scrubbers. Critics falsely claim that the capital investment for pollution control equipment would be prohibitive, and that resulting plant retirements will cause reliability of the power grid to falter.

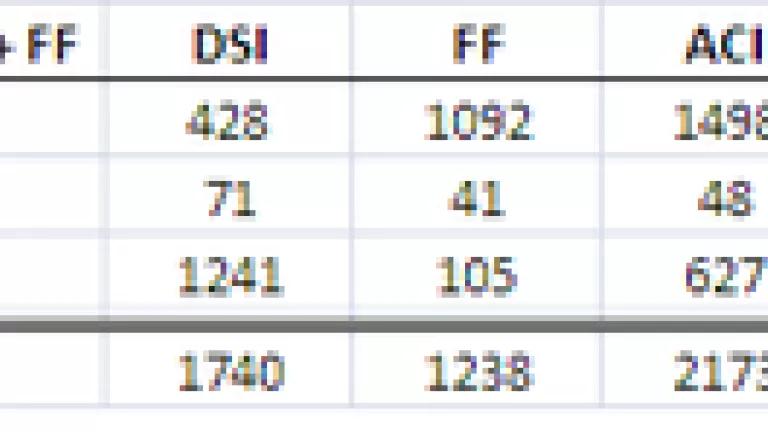

EPA’s Regulatory Impact Analysis (RIA) of the proposed standards details capital costs (annualized for 2015) for each projected control technology[1]:

Capital, FOM and VOM Costs by Control Technology for the Proposed Toxics Rule (millions of 2007$)

The RIA makes it clear that the level of capital investment in pollution control technologies associated with the mercury and air toxics standards is not prohibitive, especially when contrasted with estimates such as those from EEI, which reflect the assumption of a mercury and air toxics rule that is “sufficiently stringent to trigger the need for scrubbers, activated carbon injection (ACI) and a baghouse/fabric filter on all coal units across the United States (emphasis added).” EEI projected capital expenditures for retrofits through 2020 on the order of $27 Billion for Dry FGD, $23 Billion for Wet Scrubbers, $38 Billion for ACI and FF, $9 Billion for DSI and billions for other technologies, totaling $170 Billion[2]. Annualized for the period 2015-2020, this amounts to $34 Billion each year, far exceeding the EPA assessment of $8 Billion.[3] To put this in perspective, EEI’s assumption that the combination of scrubbers, ACI and fabric filters be installed for compliance overstates the likely cost of equipment for pollution control compliance by more than 400% on an annual basis.

Additionally, the facts show that there is no tradeoff between public health and grid reliability or even environmental performance and plant economics. To the contrary, there are cost-effective solutions for power plants to comply with the standards that would not only make electricity generation even cleaner, but also more flexible and efficient. According to a preliminary NRDC analysis based on the widely-used Integrated Planning Model (IPM) platform, NRDC has observed that:

(1) Increasing energy efficiency is the most economical way to reduce emissions and decrease overall electricity demand, and accelerating deployment of demand response is a low-cost option for adding flexibility to the power grid, while avoiding significant capacity additions across the nation. Demand Side Management (DSM), a collective term for both energy efficiency and demand response[4], can be a powerful resource in transitioning the power mix under new EPA standards. Draft preliminary results of an NRDC effort to analyze the impacts of the pending EPA Clean Air Act rules on the power sector show that increased DSM penetration minimizes projections for unplanned capacity additions of gas and coal in at least five regions of focus, including ISO-NE, NYISO, MISO, PJM and Southeast. In the preliminary analysis, accelerating deployment of demand response and energy efficiency in the near term largely offsets peak demand such that coal retirements can largely be absorbed by the system without creating a significant need for new capacity through 2020.

(2) A moderate increase in usage of already existing natural gas facilities could more than compensate for coal and oil generation going offline. On average, utilization rates of natural gas plants hover around 38% nationally. Based on calculations using data from EPA, raising this utilization rate to approximately 50% by 2015 would surpass the amount of generation lost from deactivated coal and oil facilities. Moreover, there is a substantial amount of excess generating capacity available beyond what is required to maintain reliability in the system. Reserve margins, a term which refers generally to this excess capacity, are key indicators of resource adequacy and are shown to surpass minimum reserve requirements in all regions of the country in this report by M.J. Bradley & Associates. According to the North American Electric Reliability Corporation (NERC) in its 2010 Special Reliability Scenario Assessment, there are virtually no impacts on the planning reserve margins in the short term, meaning that the ample surplus reserves in each region of the U.S. exceed NERC's reliability criteria. In the longer term, NERC provides a list of fourteen viable tools that could address resource adequacy deficiencies, should they arise. This list, found on page 40 of the report, includes solutions like using more gas-fired generation and demand side management resources, as discussed above.

EPA’s proposed Mercury and Air Toxics Standards will deliver enormous health benefits by achieving better environmental performance at the dirtiest power plants in the country. The power sector has fought Clean Air Act mercury and air toxics standards for two decades based on flawed premises, including inflated capital costs and reliability threats. With the resources available today to address reliability concerns (however unsubstantiated), including efficiency, demand response, existing energy generation from natural gas and renewable energy, there is no excuse for further delay. The Mercury and Air Toxics Standards will provide cleaner air, improved health and longer lives—all free of grid reliability impacts.

[1] EPA Mercury and Air Toxics Proposed Rule RIA, Table 8-6, pp.402-3. Available at: http://www.epa.gov/ttn/ecas/regdata/RIAs/ToxicsRuleRIA.pdf

[2] “Potential Impacts of Environmental Regulation on the U.S. Generation Fleet,” Final Report, Edison Electric Institute, January 2011. Figure 3.5: 2020 National Retrofit Capex Through 2020; p.23.

[3] This figure does not include fuel costs totaling $2.9 billion. When included, the annualized compliance cost of the rule is $10.9 billion.

[4] DR is a mechanism that makes capacity resources available during times of peak demand by allowing businesses and factories to adjust their consumption of electricity in response to market and pricing signals.