In response to growing public concerns about the safety of tar sands pipelines and the risks that tar sands spills pose to their communities, industry lobbyists at the American Petroleum Institute (API) and its surrogates have been busy making the argument that industry’s plans to transport millions of barrels of tar sands on the U.S. pipeline network requires no due diligence. The Kalamazoo tar sands spill in Michigan tragically demonstrated the consequences industry’s failure to evaluate the safety risks of the pipeline transport of tar sands diluted bitumen – after more than two years and nearly a billion dollars in cleanup cost, officials at the Environmental Protection Agency (EPA) have found that nearly 40 miles of the Kalamazoo river is still contaminated by submerged tar sands. In the face of a public increasingly concerned by proposals to build tar sands pipelines like Northern Gateway through British Columbia, Keystone XL through the Ogallala aquifer to the Gulf Coast, and Enbridge's pipeline through Canada's eastern provinces and New England, industry lobbyists have been making a number of disingenuous arguments to avoid doing due diligence. But their arguments simply do not withstand close scrutiny.

Let’s take a closer look.

Claim 1: According to API, “crude derived from tar sands has been transported by pipeline since 1968”

This statement is incredibly disingenuous. When the tar sands industry refers to crude oil derived from the tar sands, what they’re actually talking about is tar sands bitumen which has been processed in upgraders to create “synthetic crude oil.” Upgrading facilities located on tar sands mines have historically put raw tar sands bitumen through an initial refining process. While synthetic crude oil is ‘derived’ from tar sands, it is physically and chemically different than bitumen.

In our report Tar Sands Pipeline Safety Risks, NRDC raised the alarm that tar sands production had far outstripped the capacity of upgraders to process it. Rather than build new upgraders, in the late 90s industry began mixing tar sands bitumen with volatile natural gas liquids and transporting the heavy, viscous mixture – called diluted bitumen - in pipelines. It was this mixture that spilled into the Kalamazoo River in Michigan in 2010, causing the most expensive pipeline accident in U.S. history.

Claim 2: According to API, diluted bitumen is not heated for transportation in pipelines

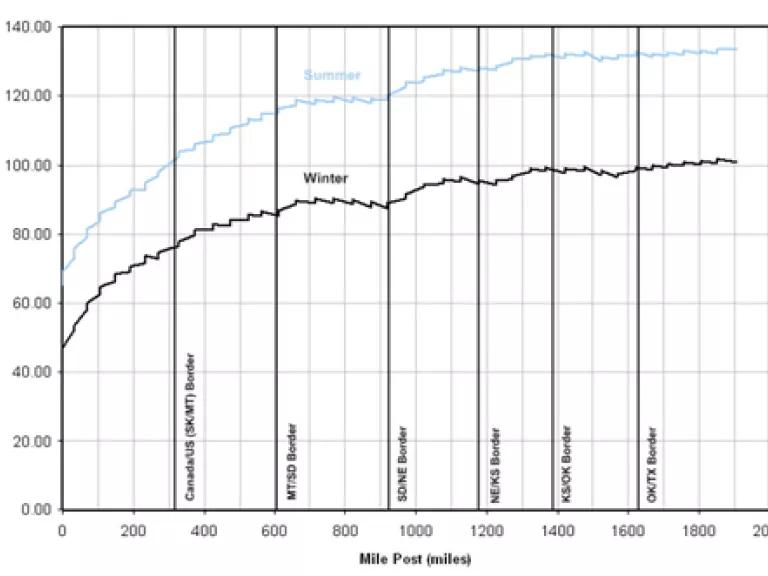

API often makes the claim that tar sands diluted bitumen is not heated from transportation in pipelines and that “the range of temperatures for all crude oils from Canada is 40 to 75 degrees Fahrenheit.” As they say, a picture is worth 1000 words, so the best place to start is TransCanada’s own temperature effects study for Keystone XL:

Figure 1. TransCanada’s temperature effects study for Keystone XL, State Department Final EIS

Now this chart may prove to be conservative – Keystone 1’s maximum temperature is listed as 158 degrees F. To clarify, tar sands diluted bitumen is so viscous, or thick, that when it is pumped at high pressures in pipelines, it generates a tremendous amount of friction which in turn generates heat. As tar sands diluted bitumen moves further down the pipeline, it gets hotter and hotter.

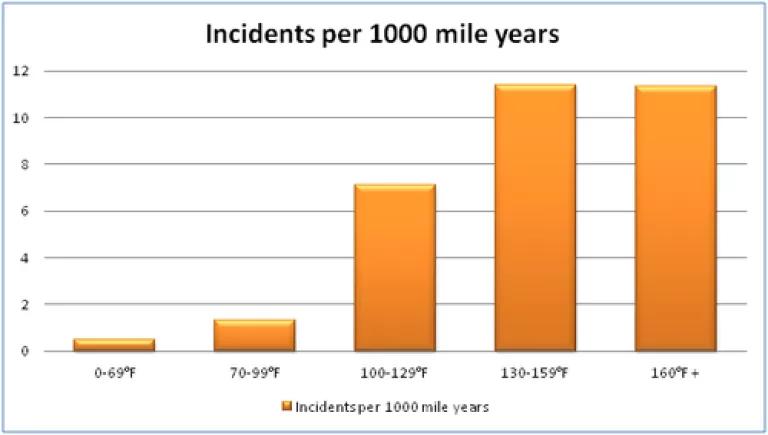

And that in itself is a cause for concern. Temperature is a known factor in pipeline spills – dramatically increasing the rate of spills due to external corrosion. A small patch of pipelines moving heavy crude in Kern county, California demonstrate the risk of high temperature pipelines. A statewide study of pipeline safety in the 90s revealed that higher temperature pipelines were almost 12 times more likely to fail due to external corrosion than ambient temperature pipelines moving conventional crude.

Figure 2. Relationship between pipeline temperature and spills, California State Fire Marshalls (CSFM) 1993

Claim 3: The U.S. currently refines heavy crude oil blends from Mexico and Venezuela which have similar properties as diluted bitumen

This is another industry red herring. While certain crudes from Venezuela and Mexico have similar levels of corrosivity as Canadian tar sands, they are not transported on the U.S. pipeline system. The U.S. Energy Information Administration (EIA) tracks imports of crude into the country with some specificity. Their databases show that heavy crudes from Venezuela and Mexico are refined on the same coastal refineries in which they’re imported. The only crudes which are moved on the U.S. pipeline systems are ones which are significantly lighter and less corrosive – similar to crudes produced in West Texas and North Dakota.

Figure 3. Satellite image of Texas City refinery - a typical coastal refinery where heavy crudes are processed at port of entry.

Claim 4: U.S. regulators at the Pipeline and Hazardous Materials Safety Administration (PHMSA) have sufficiently strong regulations to ensure the safety of diluted bitumen tar sands pipelines

That’s not what PHMSA’s Administrator Cynthia Quarterman told Congress. When asked, she told the House Energy and Power subcommittee that 1) pipeline safety regulations weren’t established with diluted bitumen in mind and 2) her agency couldn’t assure the safety of pipelines move diluted bitumen without more study.

Moreover, following the San Bruno and Kalamazoo pipeline disaster, federal investigators at the National Transportation Safety Board (NTSB) have laid blame on both pipeline operators as well as regulators at PHMSA, repeatedly citing weak regulations and poor enforcement as contributing factors.

“Pervasive organizational failures by a pipeline operator along with weak federal regulations led to a pipeline rupture and subsequent oil spill in 2010” NTSB on Kalamazoo tar sands spill, July 10, 2012

Claim 5: The Federal Energy Regulatory Commission (FERC) controls the sediment levels in pipelines in their tariff agreements

FERC doesn’t have jurisdiction over pipeline safety for hazardous liquid pipelines and doesn’t set its tariff requirements to ensure their safety. Refineries have reported significantly more sediment in Canadian heavy crudes. In fact, under FERC’s tariff requirements, a pipeline like Keystone XL could move up to 125 pounds of sediments per minute. Neither industry nor regulators have investigated the safety risks associated with these sediment levels – and doing so isn’t part of FERC’s job or expertise.

Claim 6: Analysis of pipeline failure statistics by Albertan regulators at the ERCB “hasn’t detected any significant differences between pipelines handling conventional crude versus pipeline carrying crude bitumen, crude oil or synthetic crude oil.”

This would be useful information if the ERCB had any means of detecting differences between pipelines carrying diluted bitumen and conventional crude, but they don’t. ERCB tracks conventional crude, synthetic crude and diluted bitumen pipelines simply as “crude oil pipelines.” Those pipeline categories are all tracked as “crude oil” in ERCB’s spill statistics. Until the ERCB starts collecting more precise data, it will be unable to detect problems with diluted bitumen pipelines – whether or not they exist.

Claim 7: Alberta Innovates found that Canadian tar sands had properties similar to other heavy Canadian crudes

In Tar Sands Pipeline Safety Risks, NRDC compared diluted bitumen to West Texas Intermediate, a light crude representative of the crudes historically moved on the U.S. pipeline system. It’s similar to the crude produced throughout Texas, Oklahoma, New Mexico, North Dakota and Montana. API and other industry groups claimed it wasn’t fair to compare tar sands diluted bitumen with WTI, because diluted bitumen isn’t anything like WTI. On that point we agree. However, industry groups then argued that diluted bitumen should be compared with similar heavy crudes that had not been historically moved on the onshore pipeline system in significant volumes – such as Mexican, Venezuelan or Canadian crudes.

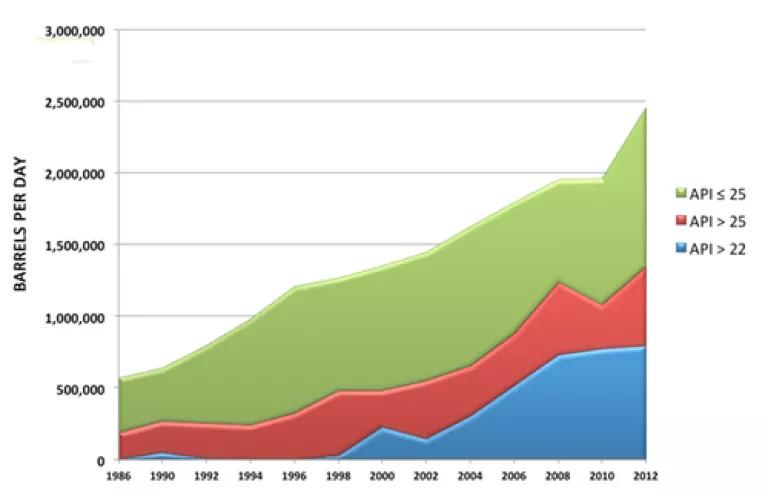

Alberta Innovates conducted such a study, comparing diluted bitumen to very heavy blends of Canadian crude which 1) required similar unconventional production processes as tar sands, 2) could not be moved in pipelines without being mixed with volatile light natural gas liquid condensates, 3) had not historically been moved in significant volumes on the U.S. pipeline system, 4) have significantly increased in production over the last ten years on the same pipelines moving tar sands.

Figure 4. Both tar sands diluted bitumen and the heavy Canadian crudes Alberta Innovates compares it to have not been historically been move on the U.S. pipeline system in large volumes, data from U.S. Energy Information Administration

As we discussed when the report came out, industry should not be allowed to avoid doing diligence regarding diluted bitumen transport in pipeline because diluted bitumen compares with a similar crude for which industry has also not done due diligence.