One of the biggest sources of dangerous air pollution from natural gas “fracking” is the whoosh of pollution that rushes from the well, like popping the top on a soda can, in the first few days after fracking is completed and the well is about to start production. What comes out are hundreds of tons of chemicals ranging from cancer-causing benzene, smog-forming volatile organic compounds (VOCs), and climate-changing methane.

Across the industry, which fracks or refracks more than 20,000 wells each year, that amounts to millions of tons of pollution that does serious harm to human health and the environment.

These are not only dangerous pollutants. They are also wasted products that can be recovered at a profit – across the industry, more than a half a trillion cubic feet of wasted gas.

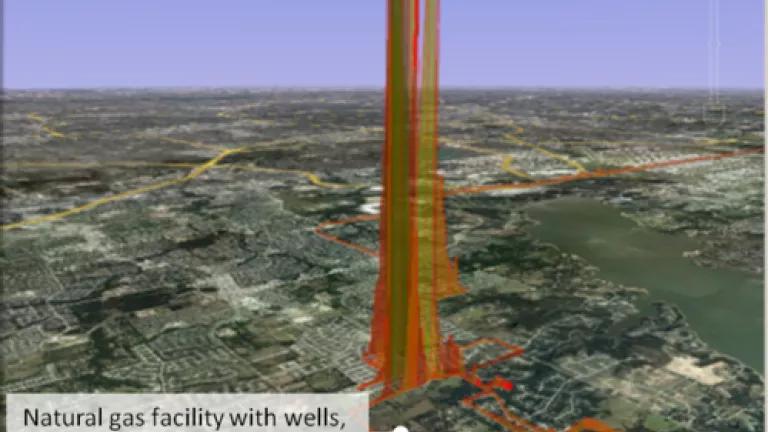

Here's an image -- a graph overlaid on a Google picture -- showing the highly-elevated methane concentrations measured directly downwind of a large natural gas facility with wells, tanks, compressors and other equipment near Flower Mound, TX.

Source: Picarro Inc., California. www.picarro.com [update: this is a different image than originally posted].

Later today, the Environmental Protection Agency is going to issue common-sense and money-saving standards to begin curbing this pollution by requiring drillers to undertake “green completions” (also called “reduced emission completions”) – using mobile, trailer-mounted tanks and equipment pictured below to capture these gases before they escape into the air and route them back into pipelines for sale as natural gas and other valuable chemicals.

Source: Colorado Oil & Gas Conservation Commission, “Proposed Rules for Green Completions” presentation June 27, 2008

NRDC documented the savings available from green completions and nine other pollution control measures in a report called Leaking Profits, steps that could recover hundreds of billions of cubic feet of natural gas -- climate-changing methane that would otherwise leak into the air -- and increase companies’ revenues by up to $2 billion per year.

But don’t just take NRDC’s word for it. As Bloomberg News reported yesterday, major natural gas drilling and production companies already use green completion systems and find them both practical and profitable. The president of Houston-based Southwestern Energy’s drilling unit told Bloomberg: “What we do today with reduced emissions completions in our wells doesn’t cost us any more than just venting the gas into the atmosphere.” He added that the company is capturing an average of 16 million cubic feet of natural gas per well – methane and other pollutants that otherwise would have been burned off or leaked into the air. Even at $2 per million Btus, he said, “we’re making money.”

Oklahoma City-based Devon Energy is one of several companies that Bloomberg reports already use green completions on more than 90 percent of their wells. A company spokesman said: “We are capturing value that would otherwise be lost. It does make good economic sense for us.”

So it’s hard to understand why the American Petroleum Institute and its reliable allies in Congress are still pushing for what you might call a “whoosh list” of delays and exemptions. Politico reported yesterday that Rep. Joe Barton (R-TX) is already proposing legislation to block these pollution standards.

API is peddling extravagant claims that green completions cost $180,000 per well. That’s not what Southwestern says: When they started doing green completions five years ago, it cost them one-ninth that amount – $20,000 per well – and now it doesn’t cost them anything extra at all. As Southwestern’s spokesman politely put it to Bloomberg, “[API’s] experience has not been our experience.”

We’ve shown in Leaking Profits and here how API has bloated how much it costs to build a green completion rig like the one pictured above and how long it will take to scale up to the needed number. There’s no reason to reward the industry laggards with years of delay.

Once there’s a federal standard, there’s every reason to expect equipment makers – including the experienced pipe and tank welders in the natural gas companies themselves – to rapidly build the needed rigs.

Colorado and Wyoming already require green completions. In the year its standards were implemented, permits for drilling more than doubled in Colorado. Drilling has not slowed in Wyoming either. The supply of green completion rigs expanded to meet the demand.

To paraphrase the movie Field of Dreams, “if you come with standards, they will build it.”

Thanks to Vignesh Gowrishankar for co-writing this post