Greetings from Shanghai! Today, NRDC is hosting a big award ceremony for 33 Chinese textile mills which completed NRDC's Clean By Design program in 2014. Our new report summarizes the awesome achievements this group of factories delivered to Planet Earth as well as to their own bottom line. 2014 was our first scale up year following the successful pilot phase of Clean by Design, and the program has proven stellar.

At today's award event, the four prominent apparel retailers and brands participating in the program will join us in the celebration - Target, Gap Inc., Levi Strauss and Co., and H&M. I'll be handing out certificates of achievement and inducting some star mills into a newly created Clean By Design "Hall of Fame". A handful of participating mills will be presenting on their accomplishments as well. Perhaps most exciting of all for me is that in the audience of more than 100, we will have an incoming freshman class of new mills about to embark on the program with us this year. Clean By Design has finally arrived!

It has been quite a ride to get to this point. More than five years ago, we embarked under an experimental notion that the poor quality of industrial manufacturing in China - far below global standards in many instances, and leading to immense pollution and wasted natural resources - presented a great opportunity to reduce environmental impact with process efficiency improvements that would save factories money.

But how would we promote efficiency improvements in industrial manufacturing there? Opportunity knocked as I looked for a lever to promote these solutions abroad - in the form of the torrent of annual corporate responsibility reports that companies were routinely arriving in my in box. In these reports, companies were routinely crowing about their deep commitment to environmental sustainability (and social responsibility). We thus fashioned a "green supply chain" initiative that provided a practical tool such companies could use to reduce their manufacturing footprint abroad.

Why did we pick the apparel industry? On merit, so to speak. Textile manufacturing, particularly the dyeing and finishing of fabric, is incredibly water and energy intensive as the process swallows up to 250 tons of water for every 10,000 meters of fabric produced and consumes 110 million tons of coal every year. China produces more than 50 percent of the world's fabric, totaling more than 80 billion meters annually. As a result, the textile industry ranks as the third largest discharger of industrial wastewater in China and the second largest user of chemicals in the country as well.

And what exactly did we do? In a nutshell, we provided a set of tools that would reduce environmental impact while saving money. The inefficient process operations typical of China were clearly wasteful, and as such, presented a juicy win-win opportunity to reduce wasteful resource use and make an impact in a big way. With Clean By Design's Ten Best Practices - a practical set of improvements that are easy to implement, low cost, and offer a quick pay back - we developed a blueprint for change that has delivered incredible results for our partners. In partnership with the brands, we recruited mills, then trained them in workshops, visited on-site with experts, assigned homework, solicited implementation plans, and quantitatively tracked what they did. The proof is in the results:

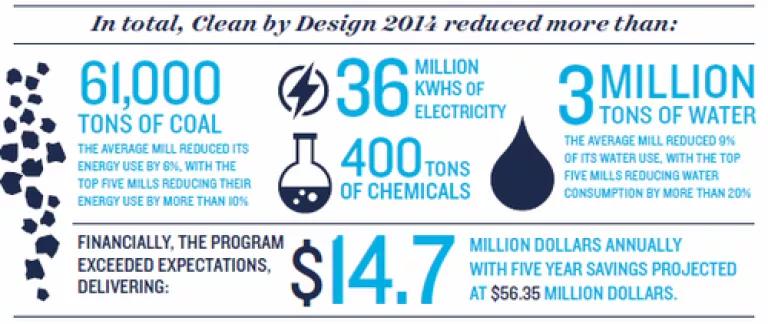

- On average, the textile mills in the 2014 class reduced 9% of their water use, with the top five mills reducing more than 20%.

- Average energy reduction was 6% with the top five mills reducing more than 10%.

- Electricity? Average reductions of 4% with the top five mills reducing more than 6.5%.

- And for those readers more interested in pocketbook issues than environmental achievement, I've got some head-turning numbers for you: this program saved a lot of money.. Clean by Design delivered, on average, savings of $440,000 in the first year, with the top five mills saving more than $880,000 - with a payback time (return on investment) of only 14 months. Better than the stock market! These resource and cost savings are annual, reflecting permanent improvements in manufacturing efficiencies, and so they will continue to deliver moving forward.

- Total reductions are impressive as well. The 33 mills reduced 3 million tons of water and 61,000 tons of coal, saving $14.73 million altogether in the first year. That's as much water as 122 million showers, and as much CO2 as emitted by 45,000 cars on the road in China in a year - and they achieved these reductions at a profit! Given that there are a rumored 55,000 textile mills in China, well, you can do the math. This program will continue to make big strides in the world's manufacturing epicenter as both Clean By Design and the sustainable apparel movement grow larger.

By now you are probably thinking it should be like a hot knife through butter to get Clean By Design to larger scale. But we have our work cut out for us. Mills without experience in the program come in skeptical that it really works, and so recruitment remains difficult. We aim to solve that challenge by having successful mill owners share how this program delivers big benefits for their business, starting at this week's meeting in Shanghai. As to adoption by multinational brands, the fact of the matter is that currently, only a handful of apparel retailers and brands (including the four companies working with us so far) are poised to develop programs that address the impacts of their manufacturing abroad. As I've blogged about previously, most sustainability programs tend to be much smaller and less impactful and focused at home in their offices or retail stores. For example, see this report for a scorecard on supply chain responsibility that grades many brands you know and love. I'll be busy improving that situation in the coming year.

But today, we can celebrate a banner day for reducing pollution in China. More and more major apparel brands are facing increasing public concern about their environmental impacts are realizing that greening their supply chain is not only crucial for global pollution reduction, it is good for business too. We'll be greening the next class of Chinese textile mills starting in June and hope to soon replicate this success across the entire industry.