Policy guide for deploying more Combined Heat and Power - a highly efficient energy technology

The Guide to the successful implementation of state Combined Heat and Power (CHP) policies was released last week, by SEE Action. CHP is a versatile technology that has great potential to generate useful energy more efficiently, and yield significant benefits for end-user facilities, utilities and communities. The Guide is a very timely and beneficial step to facilitate greater CHP deployment.

CHP system that uses a gas turbine (center) for power generation; (right) duct that carries hot exhaust gases from this step for additional power generation and/or useful heat. Courtesy: University of Illinois at Chicago.

As background, SEE Action, or the State and Local Energy Efficiency Action Network, is a state and local effort facilitated by the federal government that helps states, utilities, and other local stakeholders take energy efficiency to scale and achieve all cost-effective energy efficiency by 2020. Their work fits in well with the President’s recent Executive Order to promote industrial energy efficiency and CHP.

So what exactly is CHP? CHP (aka cogeneration) is an integrated system that simultaneously generates electricity and useful thermal energy (e.g. steam), from a single fuel. In a conventional CHP system, fuel is burned solely to generate electricity and useful thermal energy. In a variation of CHP systems, called waste energy recovery, a fuel is burned to serve an industrial process (e.g., steel production), and any unused (or “waste”) energy (e.g., process gases, in the case of steel production) from that process is then captured to generate electricity and in some cases additional useful thermal energy. [Keep an eye out for a new report by NRDC in the coming weeks for a more vivid discussion of CHP.]

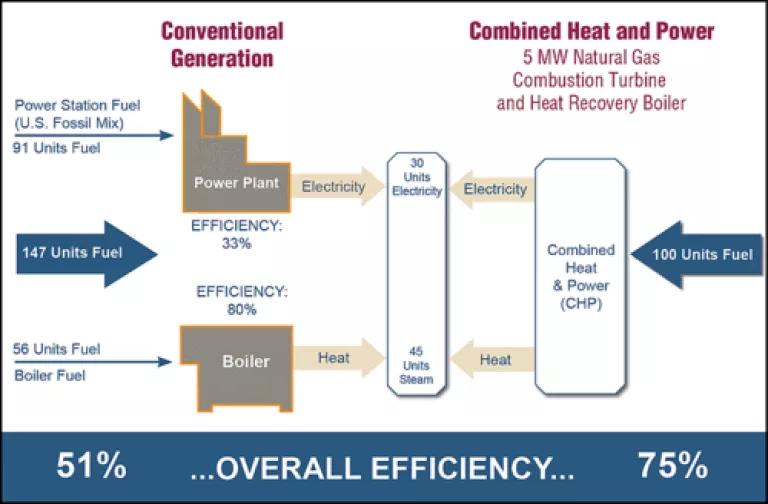

How does CHP generate energy efficiently? CHP systems can enable much more efficient generation and use of energy than systems that generate electricity and thermal energy separately (e.g., purchased electricity from the utility and thermal energy from a boiler). Conventional power stations (e.g., coal plants, combined-cycle natural gas plants) discard on average close to two-thirds of a fuel’s intrinsic energy as wasted heat, typically resulting in energy efficiency levels below 40 percent. Boilers that generate thermal energy alone are more efficient and can achieve efficiencies around 80 percent or higher. However, to meet the total electric and thermal energy needs of a given facility, power stations and boilers working independently achieve overall energy efficiencies of only around 50 percent. In contrast, CHP technologies are able to put the thermal energy that would otherwise be wasted by conventional power systems to productive use, and can routinely achieve overall average efficiency levels of 75 percent or higher (see graphic below). Furthermore, to the extent that electricity generated is used on-site, there are fewer transmission and distribution losses compared with electricity obtained from distant power plants.

How CHP systems generate useful energy more efficiently.

What are its benefits? CHP and increased energy efficiency at our manufacturing facilities, buildings and homes can help us meet our energy challenges affordably: it can save consumers money on their energy bills, drive business competitiveness, economic growth and jobs, enhance grid reliability and flexibility, and help protect our health and environment. Also, CHP is very adaptable and can be used in a variety of facilities.

Why is this Guide helpful? CHP systems are typically large systems housed at end-user facilities, e.g., manufacturing plants or large commercial buildings. They also typically need to interact with the power grid. As a result, conducive CHP policies and protocols that facilitate a streamlined interaction between end-user facilities and utilities and the power grid are essential for deploying more CHP effectively.

SEE Action’s Guide is a great step in this direction. The Guide is a thoughtful analysis of what policies and protocols could be beneficial for CHP. It adopts a principles-based approach and discusses key underpinning elements of a successful CHP policy framework. As it is at state and regional levels, rather than at the federal level, that planning and implementation of the power grid occur, the Guide looks at key state policies that impact CHP. Importantly, as different states have different requirements and constraints, the Guide only lays out a menu of options that could be practicable, but does not recommend any particular approaches. The Guide includes a discussion of:

1. Design of standby rates: Standby rates are meant to cover utility costs for providing backup power. But when these deviate sharply from the actual cost of providing service, they could pose a barrier to CHP. Standby rates that promote CHP would include features such as: offering daily or monthly “as used” demand charges for backup power and shared transmission and distribution; and allowing CHP users to purchase all of their backup power at market prices.

2. Interconnection standards (for CHP without electricity export): Even if CHP systems do not sell power to the grid, they still need to be interconnected to it for overall grid reliability. Standardized technical requirements, a streamlined application process and reasonable application fees are extremely beneficial in this regard.

3. Excess power sales: In sectors with large thermal loads, sizing a CHP system to meet these loads can result in more power generation capacity than can be consumed on-site. The Guide explores three types of programs that can facilitate excess power sales, including the use of feed-in-tariffs and competitive procurement.

4. Clean energy portfolio standards: Many states have developed clean energy portfolio standards to increase the adoption of renewable energy generation, energy efficiency, and other clean energy technologies. Currently, 23 states explicitly include CHP and/or waste energy recovery as an eligible technology. To ensure optimal benefits, the standards should carefully develop robust eligibility definitions for CHP and appropriate performance-based metrics.

5 (a) Emerging market opportunities - CHP in infrastructure resiliency: If the electricity grid is impaired, a properly configured CHP system can continue to operate, ensuring an uninterrupted supply of power and heat to the facility. Clearly, this is especially important for critical infrastructure, and CHP’s benefits were seen both during Hurricanes Katrina and Sandy. Allowing CHP to contribute to resiliency necessitates improved coordination between government emergency planners and the electricity sector, which state policymakers can enable.

5 (b) Emerging market opportunities - Utility participation in CHP markets: Allowing utilities to participate in CHP markets, either by owning CHP facilities directly or providing services to customers who own and operate CHP systems, could be a potentially significant option for increasing CHP deployment. Notably, this would not require utility participation, but allow for it.

As working members of the SEE Action group on industrial energy efficiency and CHP, my colleagues and I were closely involved in the Guide's development process. We were pleased to witness the strong attendance of working group members during meetings and calls. The discussions were rich and substantive, which made for a well-thought-out Guide that fully considered a diversity of opinions and approaches.

Currently, 82 GW of CHP is installed in more than 4,100 facilities across every state in the U.S. – this is almost nine percent of all U.S. power generation capacity. But more than 130 GW of potential remains. This Guide is a terrific boost to coordinating efforts to deploy more CHP.