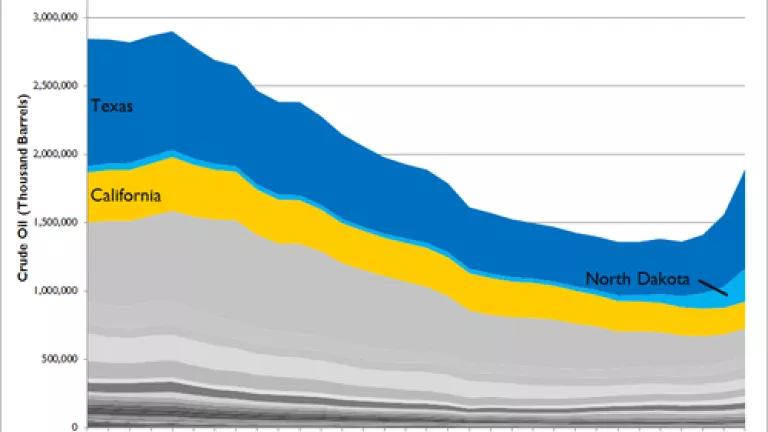

The US is in the midst of an oil boom, due in large part to advances in and the expanded use of hydraulic fracturing. This technology has allowed drillers to extract large quantities of oil from previously inaccessible formations, like the Bakken, Three Forks, Eagle Ford, Sprayberry, Wolfcamp, and other so-called “tight oil” formations, causing an exponential increase in oil production, primarily from North Dakota and Texas.

Unfortunately this drilling frenzy has also been accompanied by significant environmental and public health impacts, including water contamination, air pollution, and the industrialization of communities. As NRDC President Frances Beinecke writes, the oil boom is threatening the way of life of people living on the frontlines of this explosion in drilling.

This could be California’s future. California is sitting on one of the largest tight oil deposits in the country, the Monterey Formation, estimated to hold over 15 billion barrels of oil. But to unlock oil from the Monterey, drillers may rely not on hydraulic fracturing, but on another technique known as acidizing.

Despite being relatively unknown outside the oil and gas industry, acidizing is one of the two main forms of “well stimulation” in use today – the other is hydraulic fracturing. Like hydraulic fracturing, acidizing is used to improve the permeability of the rock formation to increase production of oil or gas, and poses similar environmental and public health risks. And also like hydraulic fracturing, acidizing is largely unregulated across the country, including in California.

A review of well files reveals that oil and gas companies in California are already injecting tens of thousands of gallons of acidizing fluids into wells around the state. The following table represents just a small sample of acidizing treatments that have been performed in California from 2011-2012.

|

API Number |

Acidizing Date |

Chemicals Used, gallons |

||

|

15% Fe Acid |

12/3% HCl/HF |

ClayFix |

||

|

2/4/2011 |

8,358 |

21,038 |

14,948 |

|

|

2/21/2011 |

11,802 |

29,526 |

8,526 |

|

|

2/23/2011 |

18,102 |

45,300 |

37,890 |

|

|

3/16/2011 |

13,650 |

34,188 |

16,842 |

|

|

3/30/2011 |

15,105 |

30,200 |

13,999 |

|

|

12/1/2011 |

70,812 |

- |

41,916 |

|

|

12/27/2011 |

52,500 |

- |

22,722 |

|

|

2/7/2012 |

31,290 |

64,800 |

24,381 |

|

|

2/11/2012 |

16,296 |

18,900 |

26,754 |

|

|

4/16/2012 |

49,258 |

77,440 |

115,277 |

|

- 15% Fe Acid is a mixture of water, hydrochloric acid (15% concentration), iron control agents, and potentially other unknown chemicals (see e.g. product sheets here and here).

- 12/3 HCl/HF is a mixture of water, hydrochloric acid (12% concentration), hydrofluoric acid (3% concentration), and potentially other unknown chemicals.

- ClayFix is a product used to flush the acid out of the well. The chemical contents of this product are unknown.[1]

Hydrofluoric acid in particular is extremely toxic and exposure to it can be life threatening. The hazards of hydrofluoric acid are unique among other inorganic acids because the fluoride ions penetrate quickly and deeply into the body. Fluoride is a calcium scavenger, pulling calcium from bodily tissue and eventually from bone, causing severe damage. At low concentrations, such as those used in the oil and gas industry, the symptoms of exposure may be delayed by up to a day, meaning that extensive damage may be done before the person seeks medical attention.

Other chemicals that may be used in acidizing fluids include corrosion inhibitors, surfactants, clay-stabilizers, solvents, and iron control agents. These products are composed of a range of chemicals, some of which may be toxic or otherwise hazardous. Many are the exact same products used in hydraulic fracturing fluids.

Finding these well files required a mixture of luck and time – clicking well-by-well through the Division of Oil, Gas, and Geothermal Resources’ (DOGGR) well database and reading through records written in drilling shorthand inscrutable to those not familiar with the language. California’s oil and gas regulations do not require drillers to disclose the volume or composition of acidizing fluids, and even when they do so voluntarily, the disclosure is far from complete or accessible.

Fortunately for Californians, a bill is moving through the legislature that would change this, Senator Pavley’s SB4.* Among other things, the bill would require oil and gas operators to apply for and receive a permit prior to performing acidizing or hydraulic fracturing, notify nearby residents and landowners, and disclose to the public the chemicals used. Many additional protections are needed, but this bill is a good start to reducing the environmental and public health risks from hydraulic fracturing and acidizing. As my colleague Damon Nagami writes, NRDC continues to support a moratorium on all new well stimulation until effective safeguards are in place.

An explosion in oil drilling may be in California’s future, but acidizing and hydraulic fracturing are happening now. All forms of well stimulation must be subject to common sense regulations to reduce environmental and public health risks.

*Update 13 September 2013: Last-minute amendments to SB4 created loopholes that will exempt some well stimulation activities from the proposed requirements. These include qualitative loopholes in the definition of “well stimulation” and a requirement for DOGGR to “establish threshold values for acid volume applied per treated foot of any individual stage of the well or for total acid volume of the treatment.” The latter means that acid stimulation operations that are below these thresholds will not be subject to the regulations required by this bill – in other words, can be conducted without a permit, without disclosing the chemicals used, and without notifying people living nearby.

See my colleague Damon Nagami’s blog for other concerns we have about the last-minute changes to the bill.

[1] A number of products are manufactured under the name “ClayFix,” see e.g. product sheet here.