This blog was drafted by Joshua Axelrod, NRDC legal consultant

A recent report prepared for tar sands giant Canadian Natural Resources Ltd. (CNRL) raises new questions about the safety of the industry’s drilling (or in situ) operations. The new revelations cast further doubt on the viability of the tar sands industry’s bullish predictions about the future of tar sands development in Northern Alberta. Among the report’s findings is the significant probability that CNRL’s high pressure steam extraction methods played a significant role in four tar sands underground spills so pressurized that tar sands oil had been bubbling to the surface for more than nine months into Canada’s Boreal Forest from CNRL’s Primrose in situ operation. These findings, along with rising production costs, the delay of pipelines like the proposed Keystone XL tar sands pipeline, the carbon intensity of in situ operations, and the fact that these well blowouts create risks to both surface and ground water raise serious questions about the pace of future development in the tar sands region.

Last summer, international attention was focused on the unmanageable risks of in situ (or drilling) tar sands development. On July 23, 2013, Mother Jones broke the news to Americans that an in situ tar sands operation in Cold Lake, Alberta, owned by CNRL, had already been leaking for nine weeks (Canadian media reported on the situation as early as July 2). Major American and international media outlets like the New York Times, the Wall Street Journal, Bloomberg, and Reuters picked up the story. Other outlets like the Huffington Post and the Toronto Star published images of the mess that tar sands was making as it seeped into the surrounding forestland. Initially, regulators did little to focus attention the issue as we discussed here but international press coverage led to more direct oversight. Now, more than a year later, the leak appears to have stopped—but not before at least 311,000 gallons of oil leaked and 91,000 tons of soil and vegetation were removed.

As the leaks persisted, CNRL insisted that the cause was the existence of aging well bores that had been abandoned for years. As recently as March 6, 2014, in fact, CNRL’s CEO Steven Laut assured investors that old well bores were the cause and that the problem was “totally solvable.” CNRL’s own report on the cause of the leaks now shows that these claims were misleading and obscure a much more serious problem with the tar sands extraction technology currently being pioneered by CNRL.

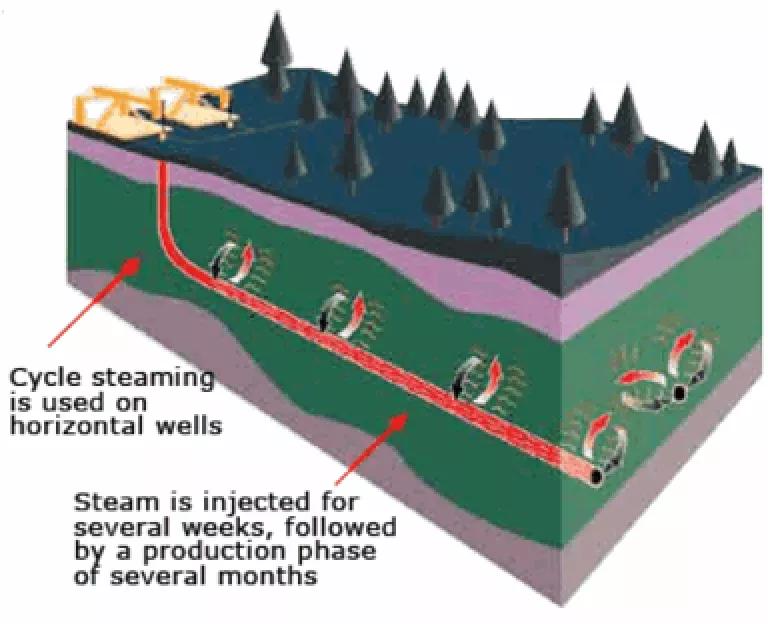

CNRL’s technology, known as “high pressure cyclic steam stimulation” (HPCSS), is a new approach to the older CSS process where operators continuously inject super-heated, highly pressurized steam down a well bore to “soak” the tar sands reservoir until the bitumen begins to separate from the sand. This pressurized soaking process creates fractures through which bitumen then flows back to the well bore and is pumped to the surface (similar to hydraulic fracturing or “fracking” which leads to the release of natural gas from underground deposits). The problem is, for HPCSS to work without causing a well blowout, the rock above the tar sands deposit must be strong enough to withstand the pressure created by the injected steam.

In CNRL’s report, several problems that threaten the future viability of HPCSS are highlighted. These include findings that vertical fractures created by the injection of pressurized steam may have provided the pathways to the surface that led to the extensive leaks. Other findings suggest that the shear pressure of the steam used was strong enough to lift “the overburden[,] resulting in a subsequent increase in vertical stress above the steaming area,” and that this resulting increase in stress may have contributed to the blowouts.

This latest development continues a string of problems for in situ operations, which have been touted by the tar sands industry as a “green” alternative to surface mining operations around Ft. McMurray because they require fewer surface disturbances. However, recent studies of the emissions and energy demands of in situ recovery methods suggest that extraction via steam may actually lead to a net energy loss (i.e., it takes more energy to get the tar sands out than will be produced after the tar sands are refined into fuel oils). Further, because of the excessive energy demands of in situ extraction, the method is highly carbon intensive and increasingly expensive as the costs of natural gas have risen in recent years. These challenges led the Canadian Association of Petroleum Producers (CAPP) to reduce its 2030 production outlook from the tar sands by 400,000 barrels per day, with most of this reduction due to the scaling back of in situ operation plans.

As CNRL awaits the Alberta Energy Regulator’s final report on the Primrose well blowouts, it is time for the tar sands industry and those who regulate it to step back and consider the risks of unbridled development in an ecologically sensitive region. For others, this latest report once again highlights the environmental impact of the tar sands and gives yet another reason for President Obama to reject the expansion-enabling proposed Keystone XL tar sands pipeline.