Recover, Reclaim, Reuse—the Coolest Way to Manage Refrigerants

Washington State leads the way by proposing a bounty on super-polluting HFC refrigerant gases.

iStock

This blog was coauthored by Christina Starr of the Environmental Investigation Agency and Kate White Tudor of White Tudor LLC.

This week, Washington State held a hearing on HB 2401, a first-in-the-nation bill on recovery, reclamation, and reuse of refrigerants. Sponsored by State Representative Davina Duerr and Environment & Energy Committee Chair Beth Doglio, this bill provides the missing link—a “bounty” payment to incentivize technicians to recover refrigerants instead of venting them.

Background

Refrigerants are essential for our economy and well-being. Our food supply depends on refrigeration at every stage of the “cold chain” to safely bring perishable food to the supermarket. Refrigerants are made to absorb and transfer heat. In your home and in supermarkets, refrigerators absorb heat and transport it to the outside, keeping food cold. In your home, your air conditioner (AC) or heat pump does the same thing: Refrigerants inside your AC or heat pump absorb heat from the outside and bring it inside to heat the house, and the other way around to cool the house.

Ironically, the things that keep us cool are also warming us up. Most of the refrigerants used today are among the worst offenders when it comes to global warming. Fluorinated refrigerant gases are used in our ACs, heat pumps, and supermarkets—most of them, hydrofluorocarbons (HFCs)—and they are 2,000 to 4,000 times more potent than carbon dioxide (CO2) in warming the planet, if released into the atmosphere.

The world has mobilized to tackle the threat from these super climate pollutants. Under the Kigali Amendment to the Montreal Protocol, 156 countries, including the United States, have agreed to an HFC phasedown, to stop producing and using these harmful gases. And we are switching to better alternatives in new equipment. However, we are still left with massive banks of HFCs and other fluorinated gases (collectively called “F-gases”) locked inside legacy equipment, where they remain a potential time bomb for the climate.

In 2022, NRDC, the Environmental Investigation Agency (EIA), and the Institute for Governance & Sustainable Development (IGSD) published a joint report and blog illustrating the tremendous climate opportunity we can unlock by better management of F-gases. Globally, good life-cycle refrigerant management can help avoid 90 billion tons of greenhouse gas emissions this century. You read that right.

Defusing the F-gas bomb

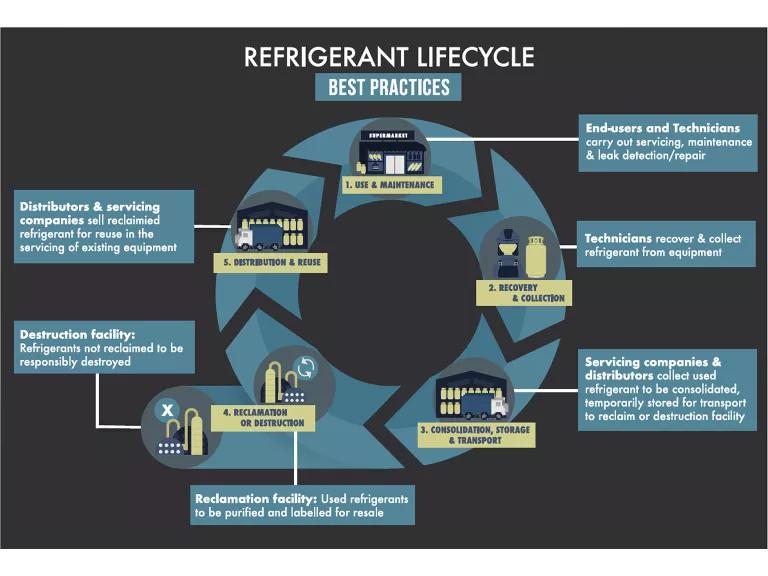

Many refrigeration systems, ACs, and heat pumps installed today will be operating for the next two decades. In an ideal world, as old systems retire, the refrigerants inside them would be recovered, cleaned up (the technical term is reclaimed), and reused to service the equipment that still needs the old refrigerants to run. Refrigerant gases can be reused after cleaning and separation, and there is a robust nationwide industry providing refrigerant reclamation services for big users.

But one of the main problems is refrigerant recovery. Most of the refrigerants are being vented instead of recovered, mainly because of a lack of incentives for technicians to take this simple step. This means there isn’t enough recovered refrigerant to reclaim in the United States today. The U.S. Environmental Protection Agency (EPA) is trying to fix that. As part of the HFC phasedown, the EPA is planning to require the industry to use increasing amounts of reclaimed refrigerants because it helps reduce the demand for newly produced HFCs and minimizes their release into the atmosphere. The proposed regulation is aimed at creating market demand for reclaimed refrigerants that will, in turn, lead to greater recovery and minimize releases to the atmosphere. But time is short, and we need other mechanisms that boost refrigerant recovery, especially as we approach the next steps in the HFC phasedown.

Extended Producer Responsibility (EPR) programs

EPR programs are the gold standard for sharing responsibility throughout the supply chain and creating incentives for better recovery, recycling, and end-of-life disposal of products. Many states have implemented EPR programs for various types of commodities, such as electronic waste, medicines, paint, and batteries.

Best practices during different stages of the refrigerant life cycle

Environmental Investigation Agency

Other countries are leading the way on refrigerant EPR programs. Australia and Canada have implemented refrigerant EPR programs that have succeeded in raising recovery rates. Several European countries, such as Norway and Denmark, have implemented deposit/refund programs, and Japan has taken the approach of an end-user fee.

In the United States, there has yet to be any national or state-level program aimed at offering incentives for end-of-life recovery, reclamation, and reuse of refrigerants. That may be about to change.

Washington State leads the way with refrigerant EPR legislation

Modeled after the Refrigerant Reclaim Australia program, HB 2401 requires producers and importers of bulk refrigerants and equipment to pay into a stewardship program based on how much refrigerant they bring into the state. Money collected will be managed by a nonprofit refrigerant stewardship organization and will fund cash payments to refrigerant technicians for each pound of refrigerant gas they recover and return.

It is not hard to recover refrigerant, but it does take time and energy. For busy HVACR technicians, their main financial incentive is to get to their next repair job. Washington’s legislation proposes to pay HVACR service technicians for the time and effort it takes to properly recover these gases; each pound of refrigerant recovered is one less pound leaked into the atmosphere and one less pound that must be newly produced or imported to keep the legacy equipment running.

Enthusiastic witnesses testified in support of HB 2401 at the hearing on January 22, 2024:

NRDC’s Richie Kaur said, “This bill creates the incentives we need. It will fund a payment to technicians for every pound of refrigerant they recover and return.”

Bobby Farris, CEO of Total Reclaim, noted, “Our biggest limit in the refrigerant reclamation industry is illegal venting. Creating a financial benefit for people to do the right thing is the way to move forward.”

Mike Armstrong, president of A-Gas in the Americas, noted, “There’s going to be a massive shortage of refrigerants without aggressive reclamation.…I encourage the state to aggressively accelerate the timing for this bill. These are really doable programs.”

Ruth Ivory-Moore of Hudson Technologies testified, “A bounty will go a long way to incentivizing a greater supply of recovered refrigerant, which can then be reclaimed and reused.”

Christina Starr of the EIA noted, “This program cost will range from $1 for a home refrigerator to about $40 for a residential heat pump. It’s insignificant as a percentage of the total cost of a new air conditioner or refrigerator.…This bill represents a major climate leadership opportunity for the state of Washington to be the first state in the nation to tackle this issue.”

This EPR bill will complement Washington State’s regulations that mandate better leak management from refrigeration and AC equipment. Refrigerant EPR programs like this will also support the EPA’s efforts as it implements HFC-reducing regulations under the American Innovation and Manufacturing (AIM) Act.

With growing interest in improving the life-cycle management of refrigerants and reaping the tremendous climate benefits, EPR programs represent a promising approach for taking action on super-polluting HFCs and other F-gases. Washington State’s legislation should be a model for states looking to bolster future refrigerant gas supplies and to take action to protect the climate from super-polluting fluorinated gases.