Next week on April 17th, EPA is expected to finalize its standards aimed at reducing harmful emissions from the natural gas industry, including fracking. NRDC believes that these rules are a good start and must be implemented without loopholes, but even more can be done.

Two weeks ago, NRDC released a new report titled, “Leaking Profits: How the U.S. oil and gas industry can reduce pollution, conserve resources, and make money by preventing methane waste”. The report finds that we have the technologies – technologies that are technically feasible, tried, tested, and demonstrated to be commercially profitable – to reduce emissions from the natural gas industry as specified by EPA’s rule. In fact, in our comments to EPA last November on the proposed rule, we provided similar evidence in support of the favorable economics of these emissions control technologies. Read on for a flavor for how the economics stack up.

Natural gas is made up primarily of methane, which is what makes natural gas a useful fuel when burned, but is an extremely potent global warming pollutant if simply allowed to leak into the atmosphere. Natural gas also contains Volatile Organic Compounds (VOCs), which contribute to ozone and associated asthma and respiratory impacts, as well as Hazardous Air Pollutants (HAPs) such as benzene, a powerful carcinogen that is also associated with neurological problems. In essence, EPA standards aim to reduce the harmful emission of natural gas into the atmosphere where its constituents can have adverse human health and environmental impacts. The EPA standards consist of two parts: the New Source Performance Standards (NSPS) that control VOC emissions and as a co-benefit methane emissions; and the National Emission Standards for Hazardous Air Pollutants (NESHAPs) that control HAP emissions.

A question in your mind at this point is probably “why would the oil and gas industry allow natural gas to be leaked into the atmosphere, when it can be used as a fuel instead?” The answer to that is quite simple. While most of the natural gas is piped and sold, at least 2 to 3 percent of the natural gas produced is allowed leaked into the atmosphere because it comes from sources that typically need additional emission control equipment accompanied by robust practices to keep emissions in check. Many of these emission control technologies are actually profitable, but just not as profitable as some other investments the oil and gas industry could make. As a result, these harmful emissions are just allowed to leak into the atmosphere. These emissions add up quickly – more than a third of all methane emissions in the U.S. come from the natural gas industry.

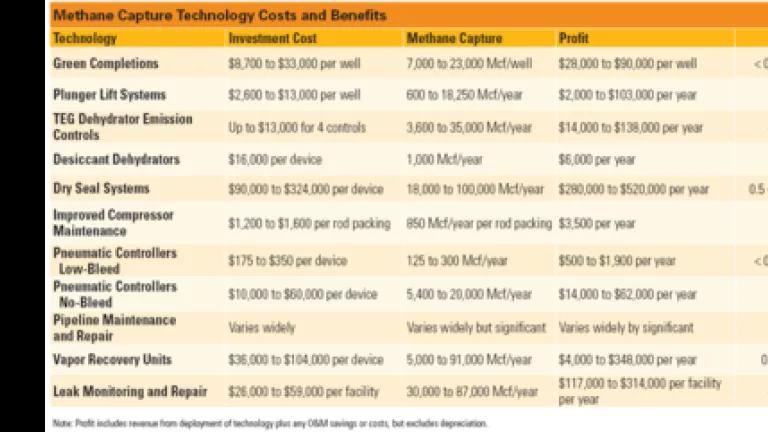

What makes control technologies profitable? While there is usually a modest upfront cost to technology implementation, this is more than compensated by the sale of substantial amounts of captured natural gas as a fuel (that would otherwise have been leaked). Sometimes there are additional operational and maintenance costs for some technologies, but in other cases there are savings. In general, the savings outweigh the costs leading to net profits. Our report analyzed the economics of 10 of the top technologies that can prevent the leakage of more than 80 percent of the industry’s current methane emissions. The payback period for these 10 technologies ranges from a few months up to three years. And profits continue after that.

My earlier blog on the report and our factsheet should give you a sense of what these 10 technologies are and where they can be used. Seven of these technologies are required, in some form, by the new EPA standards (see figure below).

My blog on green completions explained the economics of this control. Another example of a relatively simple practice that can help prevent leaks and make money is improved compressor maintenance of reciprocating compressors, which are used during natural gas processing and pipeline transportation. Changing the rod packing (think of it as a seal) regularly will help keep the seal effective. Proper functioning of the rod packing could also reduce frictional energy losses, wear and tear of the reciprocating rod (which is more expensive to replace), and reduced compressor downtime for other maintenance. Such a simple change could reduce up to nine percent of the industry’s methane emissions.

Here’s a snapshot of the favorable economics of the top 10 technologies

(click image for larger view).

Some industry players have claimed that EPA’s standards would stifle natural gas production. We believe that some of the cost estimates underlying these conclusions have been arrived at using flawed logic and assumptions as summarized in my recent blog. Contrary to industry’s claims, we strongly believe that the underlying economics are very favorable, based on ample evidence from EPA and the industry as documented in our report. Additionally, the EPA standards will provide just the certainty needed to drive the demand for and consequently the supply of control equipment. Furthermore, the oil and gas industry has in particular demonstrated that it is capable of rapidly scaling up production, evidenced by its drilling thousands of shale wells in the past few years – we have confidence in the industry’s ability to implement emission control technologies at scale, while boosting their bottom-line.