How U.S. Industry Can Support the Economy and Cut Emissions Through Combined Heat and Power - and Help Fulfill President Obama's Climate Plan

When President Obama announced his Climate Action Plan at Georgetown University recently, he called for an end to the era of unlimited carbon pollution from U.S. power plants, directing EPA to come up with a flexible, state-based plan to cut their emissions. He also expanded current programs to further tap energy efficiency in various ways.

Combined heat and power — or CHP systems — could play an important role in that plan by raising energy efficiency and wasting less energy. And through a flexible framework, CHP systems could cut emissions from power plants, which now represent 40 percent of the United States' total carbon pollution output.

CHP (see NRDC report) is an on-site energy system that can generate necessary electrical and thermal energy much more efficiently, thereby significantly boosting overall energy efficiency. They can reduce reliance on power plants and cut total fuel usage. CHP systems of various sizes and types can be configured for use in a wide spectrum of industries, such as advanced manufacturing, food processing, health care, chemical manufacturing and metal production. They can also be used at non-industrial facilities including data centers, hotels, multi-family housing, district energy sources, landfills and farms.

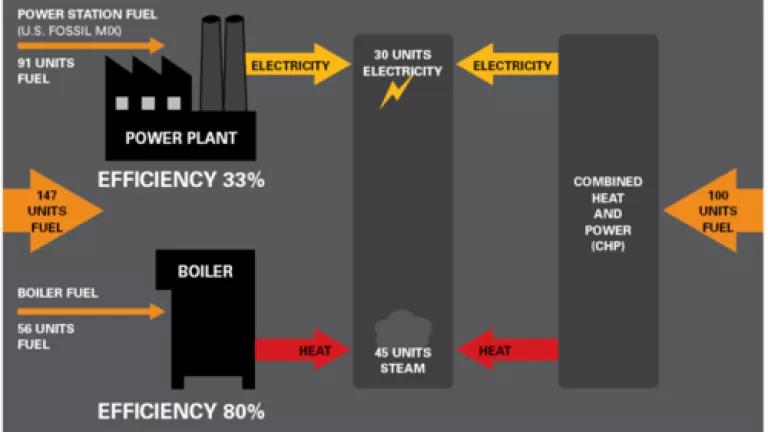

On average, conventional power stations such as coal plants discard close to two-thirds of a fuel’s intrinsic energy as wasted heat, typically resulting in energy efficiencies of around 40 percent. At an industrial facility, for example, boilers that generate thermal energy for on-site needs are much more efficient, typically 70 to 80 percent. Together, however, their aggregate efficiency is only around 50 percent.

In contrast, CHP technologies that are used on-site are able to put the thermal energy that would otherwise be wasted by conventional power stations to productive use by serving on-site thermal needs, routinely achieving overall average efficiency levels of 75 percent, or higher. And because electricity is generated and used on-site, there are fewer transmission and distribution losses compared with electricity obtained from distant power plants.

CHP systems have significantly higher overall efficiency than separate electric and thermal systems. (Adapted from U.S. EPA schematic.)

On-site CHP systems are a key way by which industry can become more efficient. The other way is to install more efficient lighting, heating and cooling systems, pumps, motors and other equipment, and to streamline industrial processes themselves. Both approaches are incredibly important and should be implemented together. Improving U.S. manufacturers' energy efficiency usage will help companies cut their energy costs, retain and grow U.S. jobs, avoid industry flight to other countries and reduce global warming pollution.

My colleague Christina Angelides and I released NRDC’s first report on CHP a few weeks ago. The report — a primer on CHP — demonstrates that CHP is a key energy-efficiency technology and can provide myriad and significant benefits. Moreover, CHP is incredibly versatile and can be deployed in a wide range of sectors, as we highlighted via 30 case studies, and there is much room for greater CHP deployment.

For the end-user facility, efficiency reduces energy costs. A CHP system could also offer new revenue streams, such as the sale of electricity, steam or both. Together, these advantages boost a company's competitiveness, worker retention and growth — even brand image. For example, CHP systems can help companies win ENERGY STAR awards presented by EPA, which can boost corporate recognition and product differentiation.

Energy reliability is another notable advantage, since CHP systems can operate through grid disruptions, as demonstrated at Co-Op City in the Bronx, and Sikorsky Corporation in Stratford, CT, during Hurricane Sandy, and the Baptist Medical Center in Jackson, MS, during Hurricane Katrina. These benefits make a promising business case for CHP; the upfront investment is usually paid back in just three to seven years.

A 38-MW CHP system at ArcelorMittal's steel plant in East Chicago, Ind. (Courtesy: ArcelorMittal)

For communities, CHP systems provide health and climate benefits by reducing total emissions (less fuel burned while generating more useful energy); integrate cleaner energy sources, such as sustainably-produced biogas, biofuels and waste-energy; create jobs for the community (both direct jobs in the installation and operation of the CHP systems and indirect jobs throughout the supply chain); and minimize costly power-plant investments, potentially reducing energy bills for customers.

For utilities, CHP systems can provide greater planning and operational flexibility, added grid reliability and improved compliance options for meeting environmental standards, such as reducing emissions from new and existing power plants as per the President’s plan. For instance, in an appropriately designed framework that counts and credits emissions reductions, a region’s overall energy-related emissions could be lowered by virtue of emissions savings from deploying a greater number of energy-efficient CHP systems.

CHP is not new. But, it is more reliable, technologically capable and cost-effective than ever before. The U.S. currently has 82 gigawatts (GW) of CHP, representing about 9 percent of total generation capacity. Nonetheless, much more potential remains. The nation could deploy an additional 50 GW with reasonable economic returns, ultimately reaching a viable 130 to 200 GW of energy, a sizable portion of which lies outside the industrial sector.

However, its benefits alone are insufficient to realize CHP's maximum market potential. We need enhanced public awareness and education about CHP's versatility and potential, coupled with proactive and strong commitment from businesses, suitable facilitation by utilities and conducive policies and regulations from all levels of government.

Efforts to promote CHP by some states like Ohio, President Obama's recent Executive Order and Climate Action Plan, and a DOE/EPA-led CHP Guide are steps in the right direction.

NRDC is working with government, labor and manufacturers to make sure that all cost-effective energy efficiency opportunities are captured – keep an eye out for CHP. I will describe some CHP case studies in an upcoming blog